After the table has been designed and dimensions applied in scale, the forming starts. The picture above shows the form laying on it's side which will be the easiest to pour this project. The styrofoam knock outs have been positioned in place and screwed in to hold steady while pouring.

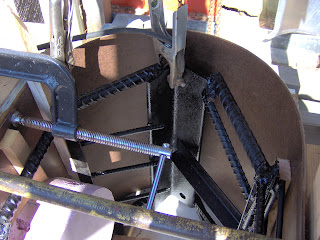

Once everything is where it should be, the rebar reinforcement is cut,fitted,welded,cleaned,and sealed. Because the wave table wasn't designed to have an end support,the steel supporting and connecting the top to the bottom is made up of heavier bars. Additional bars add to the rigidity by transferring weight and making it a strong armature. When the concrete is poured, it will bond to the steel and fill in the voids making it one solid piece.

Here the inner form is put in thus sealing the bulkheads and knockouts. Spacer blocks are inserted between the forms and the rebar to make sure the proper spacing is kept while adding the concrete. They will be pulled out when pouring.

The forms are checked for plum and level again then braced.

After the piece has been removed from it's forms the grinding begins. Here the table has already been shaped and been smoothed with 400 grit diamonds. The styrofoam can still be seen within the tear drop shapes. This gets removed by hand.

The table is shown on one of my finishing carts. I designed these to move and rotate heavy pieces so that the different phases of finishing can be accomplished.